| Voir le sujet précédent :: Voir le sujet suivant |

| Auteur |

Message |

VincentB

Serial Posteur

Inscrit le: 23 Jan 2006

Localisation: Lanzarote, on arriiiive!

Âge: 62

|

|

| Revenir en haut de page |

|

|

bocorvin

Maniaco Posteur

Inscrit le: 17 Aoû 2015

Localisation: Hillegom

Âge: 79

|

Posté le: 02/09/2016 11:36 Sujet du message: Posté le: 02/09/2016 11:36 Sujet du message: |

|

|

|

Bonyour a tous,

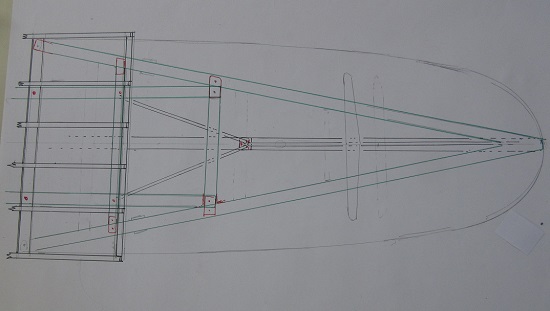

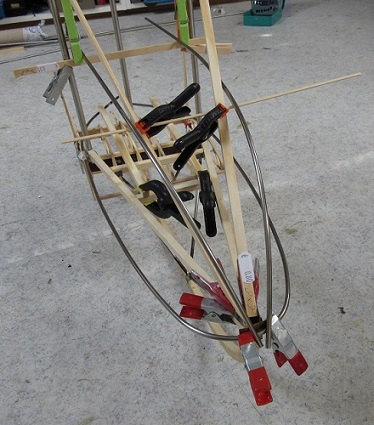

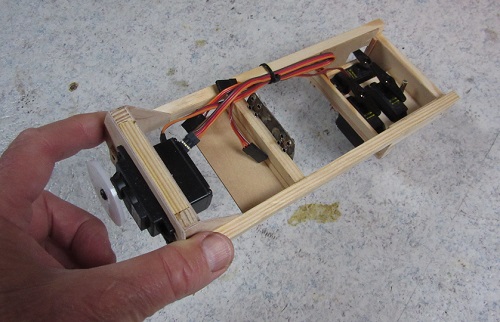

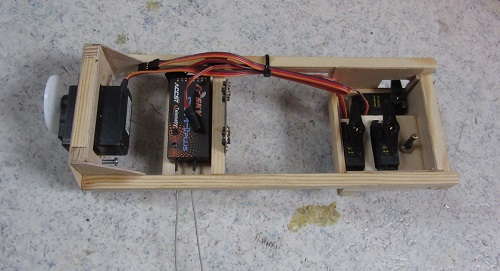

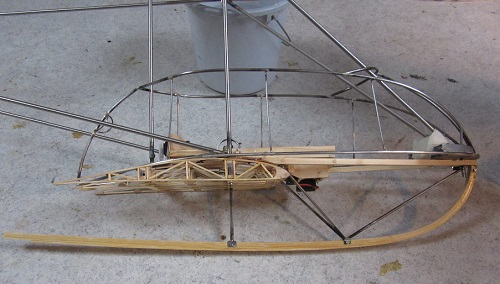

I started with the fuselage, first the nacelle. That is built of wood and steel. I tried to make a drawing based on the existing plans, photo's, thinking and guessing!

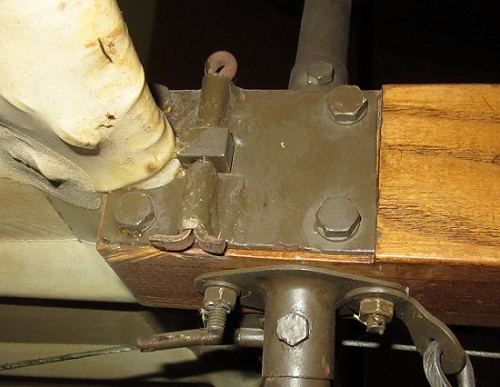

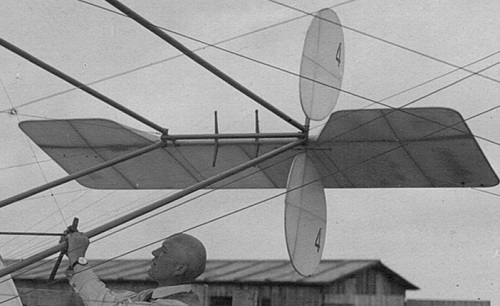

To get a better idea how fokker bolted all that wood together I visited the Aviodrome, the Dutch aircraft museum. The plane I like to see was the Spin (Spider).I was allowed to make photo's of details (thank you!). There is a snag, this was a replica of a replica, I think the basic construction of the fuselage was 90% correct.

As you can see, rather big steel profiles and big bholts are used, I'll try to keep this in mind!

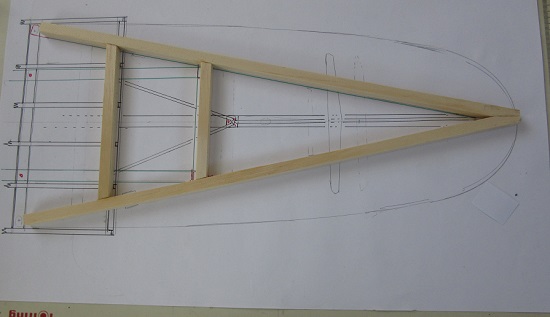

I glued the wooden frame, first out of 10mm X 10mm spruce, but looking at some photo's of the original I changed it 8mmX 8mm.

Laminated the skid, first 3 layers 3mm X 8mm spruce, later one extra layer at the bottom. I drenched the spruce in boiling water before bending. Clamped it without glue together

and put very thin cyano on it, no mess!

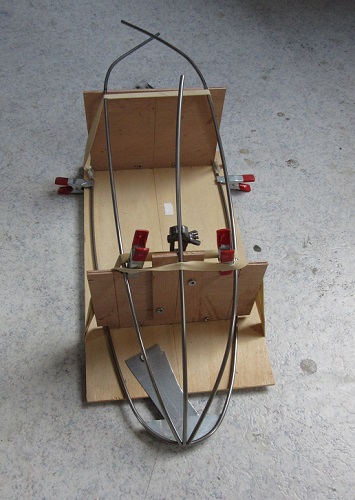

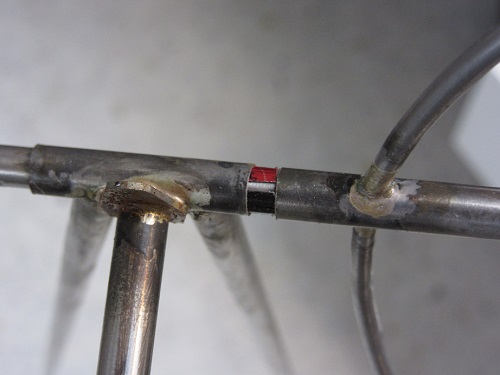

Now I had to start with the metalwork. I ordered stainless steel tubes at "tubos capillares", as recommended on the forum and within a couple of days I received a 2m long package, very good service!

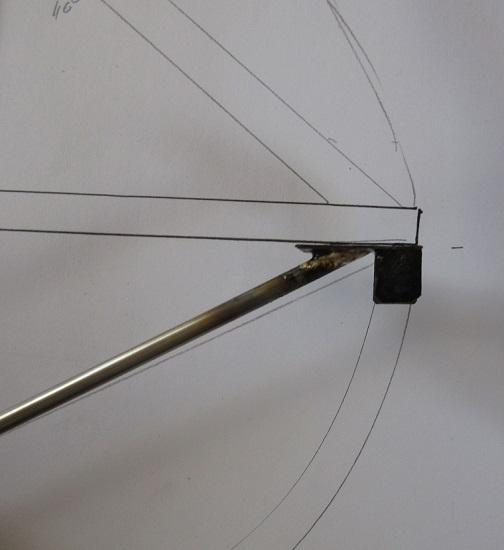

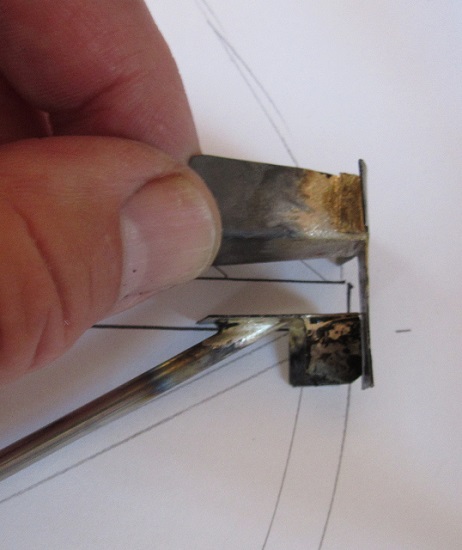

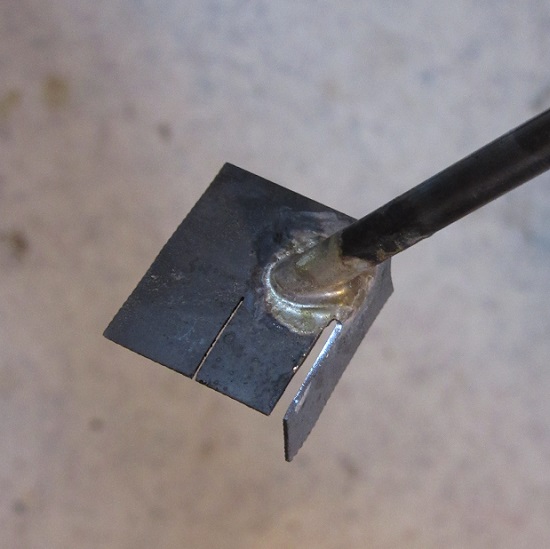

I made the supports for the skids an the piece of metal at the nose to connect the 'nose'of the 'A' and later the tubing of the nacelle. It was long ago I used silver solder and it took some time to get used to it.

After using a bigger torch thing went better, but it was sometimes difficult to keep all the parts correctly placed!

Later it will be bolted with M2 trough the wood.

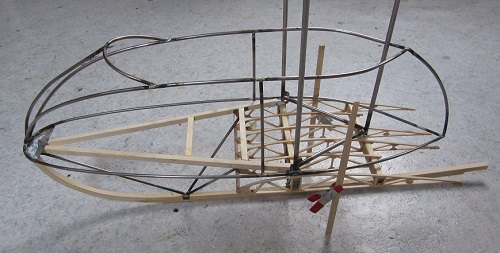

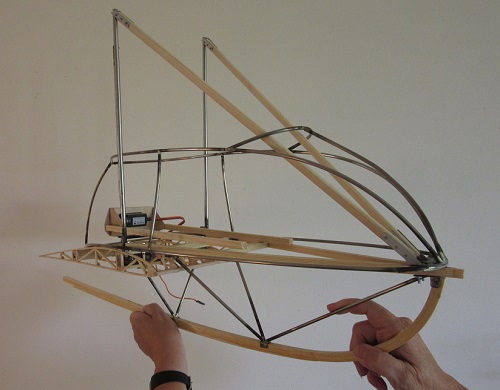

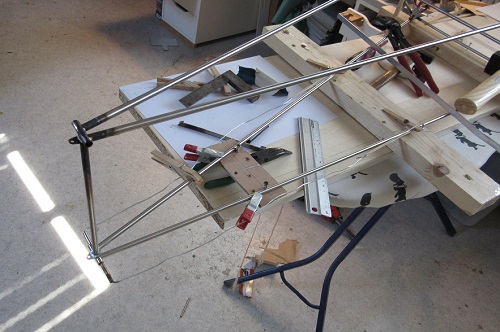

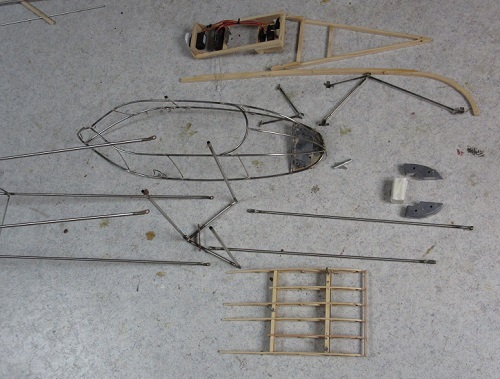

Just to get a better idea to make the tubing of the nacelle, the placing of the rc equipment and the pilots I put it temporary together.

Never built someting like this

My idea is next to make the tubing of the nacelle and a bit later detailing the wooden structure. I am not used in constructing wood with metal and there is a lot of thinking and guessing in it!

to be continued. |

|

| Revenir en haut de page |

|

|

CHAUSSEBOURG

Maniaco Posteur

Inscrit le: 22 Sep 2010

Localisation: Touraine

Âge: 87

|

Posté le: 02/09/2016 11:54 Sujet du message: Posté le: 02/09/2016 11:54 Sujet du message: |

|

|

|

Very good building and many thanks for all the détails!

Pierre

Lorsqu'on est toujours en l'air, c'est qu'on n'est pas encore posé.

Johannes Walkowiak

LDC |

|

| Revenir en haut de page |

|

|

de Schaetzen Harold

Maniaco Posteur

Inscrit le: 06 Avr 2006

Localisation: Schilde

Âge: 79

|

Posté le: 03/09/2016 06:44 Sujet du message: Posté le: 03/09/2016 06:44 Sujet du message: |

|

|

|

Prachtig! Zeer indrukwekkend. Alles is goed nagedacht.

Doe zo voort.

Harold |

|

| Revenir en haut de page |

|

|

bocorvin

Maniaco Posteur

Inscrit le: 17 Aoû 2015

Localisation: Hillegom

Âge: 79

|

Posté le: 03/09/2016 09:36 Sujet du message: Posté le: 03/09/2016 09:36 Sujet du message: |

|

|

|

Thank you Pierre for your nice comments  and Harold hartelijk bedankt en inderdaad ik moet me soms suf denken, maar dat maakt dit soort projecten spannend! and Harold hartelijk bedankt en inderdaad ik moet me soms suf denken, maar dat maakt dit soort projecten spannend!

Vincent |

|

| Revenir en haut de page |

|

|

bocorvin

Maniaco Posteur

Inscrit le: 17 Aoû 2015

Localisation: Hillegom

Âge: 79

|

Posté le: 11/09/2016 19:59 Sujet du message: Posté le: 11/09/2016 19:59 Sujet du message: |

|

|

|

Bonjour a tous,

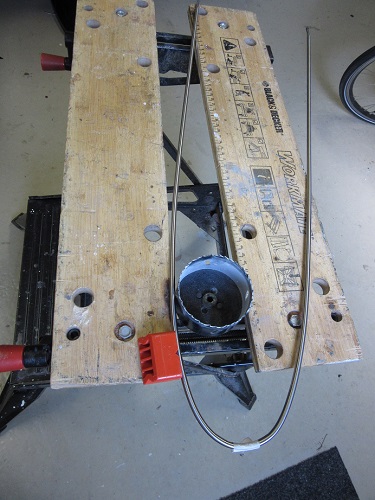

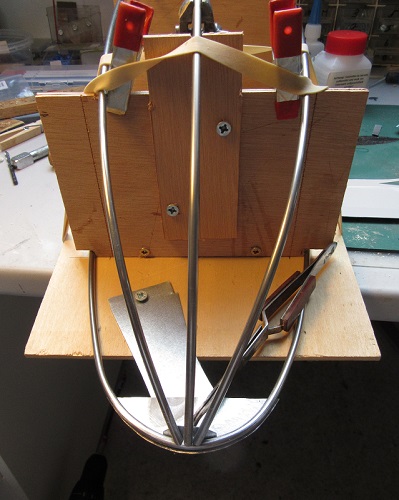

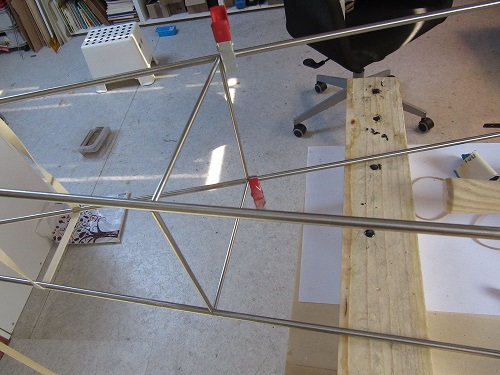

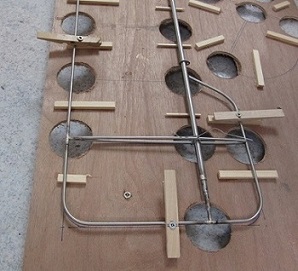

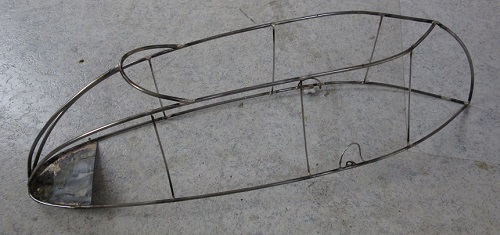

I started with the tube frame of the nacelle, made it from 6 mm stainless steel tube with a wall thickness of 0.5 mm. Luckily I had some steel wire to prevent buckling.

(found that idea in Pierre Delrieu 's article) I bend it on a workmate with a hole saw clamped in.

When I fitted this on the wing it didn't look good, the tube was to thick. (see the photo on page one of the frame of the nacelle).

I tried now to make it from 4mm tube, also with a wall thickness of 0.5 mm. It appeared to be bendable without steel wire in it! No buckles!

Onother problem was the absence of frames, so I had to make some supports to solder it.

I planned to bolt the ballast lead on the steel plate

I think it's now too flimsy so it will be deformed when covered. I made 4mm tube vertical struts, but I think I will make 3 vertical struts of 2mm solid steel, which is less obstrusive.

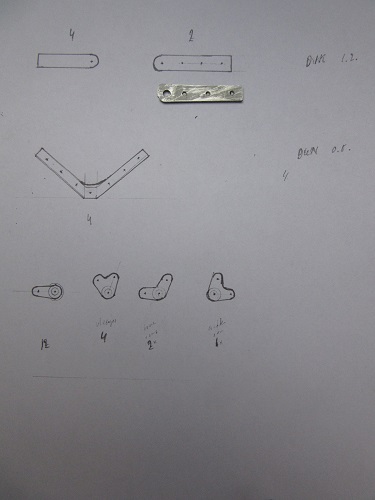

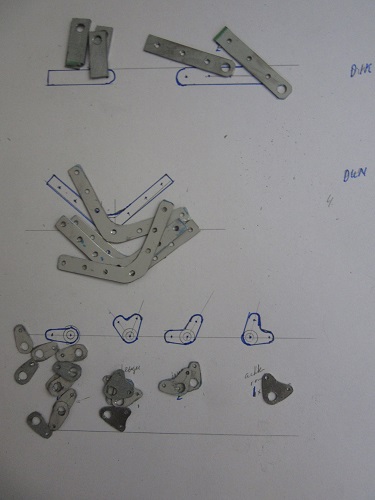

I also made the three central wingstruts (first of 10 mm, changed that in 6 mm, that is better looking) and spent a lot of time fitting the puzzle together. This is a sketch of qall the small metal parts I still have to make.

In the meantime I turned a pulley which comes on top of the rear central wingstrut.

To be continued. |

|

| Revenir en haut de page |

|

|

bocorvin

Maniaco Posteur

Inscrit le: 17 Aoû 2015

Localisation: Hillegom

Âge: 79

|

Posté le: 16/09/2016 18:50 Sujet du message: Posté le: 16/09/2016 18:50 Sujet du message: |

|

|

|

Hello everyone,

This week I made a lot of small metal parts;

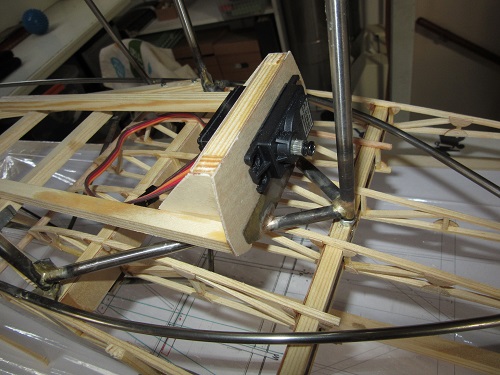

and tried to make a proper support for the "wing warping servo" a very strong servo which Claude gave to me, thanks Claude! 13.6 kg... should do the yob.

It will be attached with a couple of M3 bolts to the metal plate, so which is connected almost directly to the rear wingstrut.

From 10 X 8 mm spruce I planed a more or less tear-shaped strut to connect the nose with the center wing struts.

all connected with metal plates and M 2 bolts.

Now it was time for the tailboom, made from 6.0mm with a wall thicknes of 0.5 mm. It was a bit of a puzzle to hold everything in place, but in the end the tailboom was straight and could be fitted.

It's looking allright, but to my disappointment the tailboom is to heavy  . I read some stories about the vulnerabilty of the stainless steel, but this is definitely going to be too heavy. The positive thing is that I know how it all fits together, I learned quite a lot. So I ordered the tube with thinner wall (0.25mm instead of 0.5 mm) and next week I will build a new and lighter tailboom! . I read some stories about the vulnerabilty of the stainless steel, but this is definitely going to be too heavy. The positive thing is that I know how it all fits together, I learned quite a lot. So I ordered the tube with thinner wall (0.25mm instead of 0.5 mm) and next week I will build a new and lighter tailboom!

To be continued. |

|

| Revenir en haut de page |

|

|

sebastian92

Serial Posteur

Inscrit le: 01 Sep 2015

Localisation: Hauts de seine

Âge: 62

|

Posté le: 16/09/2016 22:34 Sujet du message: Posté le: 16/09/2016 22:34 Sujet du message: |

|

|

|

very good job ![[clap]](images/smiles/Clap.gif)

It's a pity for the weight but the arm of lever of the nose is important … of what to compensate for the weight in the back, no ?

you build very fast

Pourvu que ça vole, roule, flotte ! normalement j'ai tout bien fait pour…

Un bel avion est un avion qui vole bien ! Marcel Dassault

…………

Sebastian

••••••••••••••••••••

Vends module émission 2.4 ghz pour Futaba, Hitec TZ-FM + 2 récepteurs corona 8 voies (contact en MP)

•••••••••••••••••••• |

|

| Revenir en haut de page |

|

|

bocorvin

Maniaco Posteur

Inscrit le: 17 Aoû 2015

Localisation: Hillegom

Âge: 79

|

Posté le: 17/09/2016 07:37 Sujet du message: Posté le: 17/09/2016 07:37 Sujet du message: |

|

|

|

Thank you Sebastian for your comment!

About the weight, I didn't estimate it correctly. The tailboom weighs about 330 grams and the horizontal and vertical stabilizers should be about the same. It would need more than 1000 gram as ballast in the nose. I think it will give a hard to fly plane ![[humm]](images/smiles/humm.gif) . Halving the wall thickness of the tubes give about half of the weight I think. I don't like to do things over again, but I know there is no other way. I hope to get a good flying plane now . Halving the wall thickness of the tubes give about half of the weight I think. I don't like to do things over again, but I know there is no other way. I hope to get a good flying plane now

Vincent. |

|

| Revenir en haut de page |

|

|

GARCIA

Psycho Posteur

Inscrit le: 25 Juil 2010

Localisation: COTE D'OR

Âge: 66

|

Posté le: 17/09/2016 08:00 Sujet du message: Posté le: 17/09/2016 08:00 Sujet du message: |

|

|

|

Félicitation pour cette construction ![[amen]](images/smiles/amen.gif) ![[amen]](images/smiles/amen.gif)

José |

|

| Revenir en haut de page |

|

|

Philippe26

Psycho Posteur

Inscrit le: 10 Fév 2015

Localisation: Allan près de Montélimar

Âge: 72

|

Posté le: 20/09/2016 08:45 Sujet du message: Posté le: 20/09/2016 08:45 Sujet du message: |

|

|

|

Hi,

Yes, it's a pity this heavy tail..... but I agree, the solution is to rebuilt it with lighter tubes... no other way .

It is boring, but now you know how to do the job.....

Courage !

Philippe

Je ne suis pas vieux, je suis jeune depuis plus longtemps que vous......

I am not old, I am young for longer than you .....

"C'est impossible, dit la Fierté; c'est risqué, dit l'Expérience; c'est sans issue, dit la Raison; mais essayons, murmure le coeur » W.A.Ward |

|

| Revenir en haut de page |

|

|

VincentB

Serial Posteur

Inscrit le: 23 Jan 2006

Localisation: Lanzarote, on arriiiive!

Âge: 62

|

Posté le: 20/09/2016 10:12 Sujet du message: Posté le: 20/09/2016 10:12 Sujet du message: |

|

|

|

Tu as fait un superbe boulot Vincent ![[clap]](images/smiles/Clap.gif) effectivement si tu as utilisé du 0.5mm c'est inutilement lourd pour un empennage, mais avec du tube de 0.25mm de paroi, c'est moins lourd qu'en bois et plus rigide/solide. effectivement si tu as utilisé du 0.5mm c'est inutilement lourd pour un empennage, mais avec du tube de 0.25mm de paroi, c'est moins lourd qu'en bois et plus rigide/solide.

Retroplane et modélisme en pause, vanlife à haute dose. |

|

| Revenir en haut de page |

|

|

bocorvin

Maniaco Posteur

Inscrit le: 17 Aoû 2015

Localisation: Hillegom

Âge: 79

|

Posté le: 20/09/2016 11:06 Sujet du message: Posté le: 20/09/2016 11:06 Sujet du message: |

|

|

|

Merci Jose pour les encouragements!

Yes, Phillippe and Vincent, it was not a good idea to make the tailboom from tube with a wall thickness of 0.5 mm. It was my fear that it would buckle to easily because the tubes are very long without being interconnected (45 cm). Besides I read about the danger of the tubes getting bended. I am also not convinced it will fly easily  so I liked to have it rugged enough constructed . I have another option; when the tailboom is finished I can slide a carbon tube of 5 mm inside the 6 mm stainless steel tubes ( they are open at the front and they are straight). This adds not much weight and it gives better survival changes for the tailboom with hard landings. so I liked to have it rugged enough constructed . I have another option; when the tailboom is finished I can slide a carbon tube of 5 mm inside the 6 mm stainless steel tubes ( they are open at the front and they are straight). This adds not much weight and it gives better survival changes for the tailboom with hard landings.

I don't mind making an other one, slowly I get a better idea how Fokker got along with wood, steel, wires and canvas and its good for my soldering skills!

I am waiting for the tubes with wall thickness of 0.25 mm and also for thinner tubes for the tailplanes.

Vincent |

|

| Revenir en haut de page |

|

|

Philippe26

Psycho Posteur

Inscrit le: 10 Fév 2015

Localisation: Allan près de Montélimar

Âge: 72

|

Posté le: 20/09/2016 11:26 Sujet du message: Posté le: 20/09/2016 11:26 Sujet du message: |

|

|

|

Hi Vincent,

Effectively, an inner carbon tube can be a good solution, not too heavy, and rigid enough.

Courage !

Philippe

Je ne suis pas vieux, je suis jeune depuis plus longtemps que vous......

I am not old, I am young for longer than you .....

"C'est impossible, dit la Fierté; c'est risqué, dit l'Expérience; c'est sans issue, dit la Raison; mais essayons, murmure le coeur » W.A.Ward |

|

| Revenir en haut de page |

|

|

bocorvin

Maniaco Posteur

Inscrit le: 17 Aoû 2015

Localisation: Hillegom

Âge: 79

|

Posté le: 20/09/2016 12:19 Sujet du message: Posté le: 20/09/2016 12:19 Sujet du message: |

|

|

|

Hi Philippe,

Glad you liked the idea. I feel a bit unsecure to use carbon tube for a retroplane glider, but when I got a buckled tailboom at Fauville, I can't repair that. In normal use the carbon tube is not functional, only with hard landings or minor crashes  . .

Vincent |

|

| Revenir en haut de page |

|

|

VincentB

Serial Posteur

Inscrit le: 23 Jan 2006

Localisation: Lanzarote, on arriiiive!

Âge: 62

|

Posté le: 20/09/2016 13:12 Sujet du message: Posté le: 20/09/2016 13:12 Sujet du message: |

|

|

|

Les tubes de chez tubos capillares sont très raides, et le stab est situé très haut, donc vraiment peu de chance de l'abimer, pour moi c'est inutile d'ajouter du carbone, mais bon tu fais comme tu veux....

Retroplane et modélisme en pause, vanlife à haute dose. |

|

| Revenir en haut de page |

|

|

bocorvin

Maniaco Posteur

Inscrit le: 17 Aoû 2015

Localisation: Hillegom

Âge: 79

|

Posté le: 28/09/2016 16:09 Sujet du message: Posté le: 28/09/2016 16:09 Sujet du message: |

|

|

|

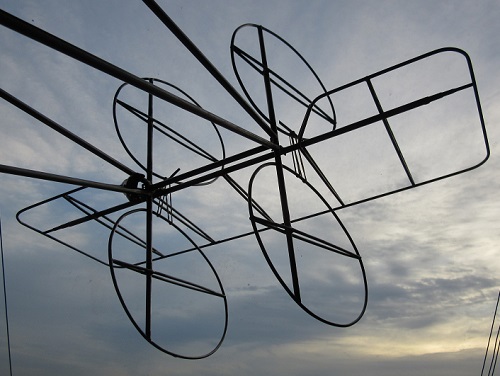

Hello everyone,

Thank you Vincent for convincing me, that the thin walled tube (0.25 mm) is strong enough!

I received the new tubes and made a new tailboom. It looks identical as the old one , but it weighes only 160 gr

Next the horizontal stabilizer; I looked at pictures from the "alte news"

http://www.collectors-edition.de/Alte%20News/english.htm in which is described how they build a exact replica's of Fokker fighters of WW1.

I also used a partly enhanced picture from Hans Disma collection

which showed a lot of info.

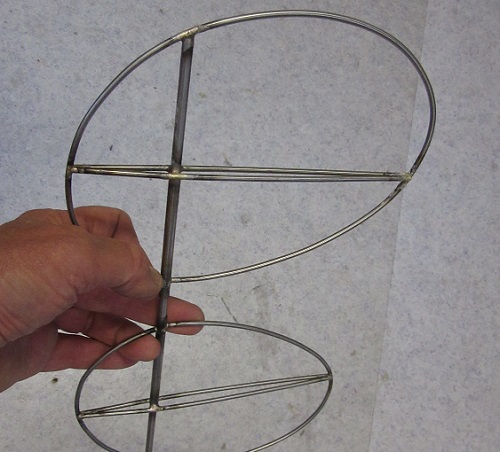

I made a jig from 4mm plywood for the horizontal and vertical stabilizers. I used 5 mm tube for the main spar and 3mm tube for the other parts.

The "rudder horns" are very caractaristic. Found some info on the "alte news" I tried to make the from steel. I started with a strip of 0.7 mm steel plate, bend it over 90 degrees and flattened on a 1mm steel plate.

grinded into shape, first with a carborundum disc, later with a diamond one.

In a similar way I made the vertical stabilizers (4 of them!)

I could bend the 3mm tube by hand, didn't buckle.

Now I put it together;

and some detail.

The weight of the tailboom with stabilizers is 365 gr.

To be continued. |

|

| Revenir en haut de page |

|

|

sebastian92

Serial Posteur

Inscrit le: 01 Sep 2015

Localisation: Hauts de seine

Âge: 62

|

Posté le: 28/09/2016 17:35 Sujet du message: Posté le: 28/09/2016 17:35 Sujet du message: |

|

|

|

Marvelous building ! ![[clap]](images/smiles/Clap.gif)

you are so equipped ! wood, steel, brasure… you touch at all… gold fingers !!

and the website you join is very interesting for details

Pourvu que ça vole, roule, flotte ! normalement j'ai tout bien fait pour…

Un bel avion est un avion qui vole bien ! Marcel Dassault

…………

Sebastian

••••••••••••••••••••

Vends module émission 2.4 ghz pour Futaba, Hitec TZ-FM + 2 récepteurs corona 8 voies (contact en MP)

•••••••••••••••••••• |

|

| Revenir en haut de page |

|

|

patte de loup

Incurable Posteur

Inscrit le: 25 Jan 2006

Localisation: Alsace (Strasbourg)

Âge: 67

|

Posté le: 28/09/2016 17:46 Sujet du message: Posté le: 28/09/2016 17:46 Sujet du message: |

|

|

|

![[clap]](images/smiles/Clap.gif) ![[clap]](images/smiles/Clap.gif) ![[clap]](images/smiles/Clap.gif)

Pat'

Un "prédateur" des pentes de France et de Navarre |

|

| Revenir en haut de page |

|

|

VincentB

Serial Posteur

Inscrit le: 23 Jan 2006

Localisation: Lanzarote, on arriiiive!

Âge: 62

|

Posté le: 28/09/2016 17:49 Sujet du message: Posté le: 28/09/2016 17:49 Sujet du message: |

|

|

|

Super chouette cet empennage ![[good]](images/smiles/good.gif) en tube tout est permis, vive le tube en tube tout est permis, vive le tube

Retroplane et modélisme en pause, vanlife à haute dose. |

|

| Revenir en haut de page |

|

|

Philippe26

Psycho Posteur

Inscrit le: 10 Fév 2015

Localisation: Allan près de Montélimar

Âge: 72

|

Posté le: 28/09/2016 18:20 Sujet du message: Posté le: 28/09/2016 18:20 Sujet du message: |

|

|

|

Hi Vincent,

If having changed tube thickness has solved your problem, perfect.

What a great job !!!

Wonderful, as said by another guy, you have golden fingers.....

Friendly

Philippe

Je ne suis pas vieux, je suis jeune depuis plus longtemps que vous......

I am not old, I am young for longer than you .....

"C'est impossible, dit la Fierté; c'est risqué, dit l'Expérience; c'est sans issue, dit la Raison; mais essayons, murmure le coeur » W.A.Ward |

|

| Revenir en haut de page |

|

|

GARCIA

Psycho Posteur

Inscrit le: 25 Juil 2010

Localisation: COTE D'OR

Âge: 66

|

Posté le: 28/09/2016 18:50 Sujet du message: Posté le: 28/09/2016 18:50 Sujet du message: |

|

|

|

![[baaave]](images/smiles/baaave.gif) ![[baaave]](images/smiles/baaave.gif) ![[baaave]](images/smiles/baaave.gif) ![[baaave]](images/smiles/baaave.gif) C'est chouette, super boulot C'est chouette, super boulot ![[amen]](images/smiles/amen.gif) ![[amen]](images/smiles/amen.gif) ![[amen]](images/smiles/amen.gif)

José |

|

| Revenir en haut de page |

|

|

Johannes

Serial Posteur

Inscrit le: 23 Juil 2007

Localisation: Leichlingen

Âge: 66

|

Posté le: 28/09/2016 19:44 Sujet du message: Posté le: 28/09/2016 19:44 Sujet du message: |

|

|

|

![[amen]](images/smiles/amen.gif) ![[amen]](images/smiles/amen.gif) Absolute Spitze Absolute Spitze ![[baaave]](images/smiles/baaave.gif) ![[baaave]](images/smiles/baaave.gif) |

|

| Revenir en haut de page |

|

|

bocorvin

Maniaco Posteur

Inscrit le: 17 Aoû 2015

Localisation: Hillegom

Âge: 79

|

Posté le: 28/09/2016 21:55 Sujet du message: Posté le: 28/09/2016 21:55 Sujet du message: |

|

|

|

Thank you Sebastian, Pat, Vincent, Phillippe, Jose und Johannes for all the nice comments!

I need it a bit, burnt fingers  need some TLC need some TLC

Next is the nacelle and steering cables, it is a very peculiar construction! Bolts, steel, wood, cables ![[argh]](images/smiles/argh.gif) I am not complaining, I enjoy it! I am not complaining, I enjoy it!

About the website "alter news" there is nothing new on it. There happened something with this wonderful project which I don't understand.

I forgot one picture, this is also an enhancement of the Hans Disma one

This gives a good idea of the rudders.

To be continued! |

|

| Revenir en haut de page |

|

|

DOMINIQUE DIOT

Incurable Posteur

Inscrit le: 03 Nov 2013

Localisation: Somme

Âge: 72

|

Posté le: 29/09/2016 08:11 Sujet du message: Posté le: 29/09/2016 08:11 Sujet du message: |

|

|

|

![[clap]](images/smiles/Clap.gif) ![[clap]](images/smiles/Clap.gif) ![[good]](images/smiles/good.gif) nickel nickel

Lorsque on est encore en l'air, c'est qu'il est encore entier.

Dominique |

|

| Revenir en haut de page |

|

|

CHAUSSEBOURG

Maniaco Posteur

Inscrit le: 22 Sep 2010

Localisation: Touraine

Âge: 87

|

Posté le: 29/09/2016 13:05 Sujet du message: Posté le: 29/09/2016 13:05 Sujet du message: |

|

|

|

Beautiful work! Congratulations

Pierre

Lorsqu'on est toujours en l'air, c'est qu'on n'est pas encore posé.

Johannes Walkowiak

LDC |

|

| Revenir en haut de page |

|

|

bocorvin

Maniaco Posteur

Inscrit le: 17 Aoû 2015

Localisation: Hillegom

Âge: 79

|

Posté le: 29/09/2016 15:24 Sujet du message: Posté le: 29/09/2016 15:24 Sujet du message: |

|

|

|

Merci Dominique et Pierre pour votre encouragements!

Vincent |

|

| Revenir en haut de page |

|

|

bocorvin

Maniaco Posteur

Inscrit le: 17 Aoû 2015

Localisation: Hillegom

Âge: 79

|

Posté le: 12/10/2016 09:41 Sujet du message: Posté le: 12/10/2016 09:41 Sujet du message: |

|

|

|

Bonjour a tous,

Last weeks I did a lot of different things. I started with the tailplanes, there was a lot of slop in the vertical ones, so I put an aluminium shim in the tube

Beercans can be very useful!

Next was the pin to hold both the vertical tailplanes together. I drilled and reamed a 1.5 mm hole through both tubes, used a nail as a pin and with a small clip from 0.6 mm steel secured it.

I also made a support for the seats in which all the rc equipment was installed. It is fixed with two M3 bolts directly to the rear vertical strut, the wing warping force will be just there. In the front of this support are the servo's for the tailplanes and tow hook.

Here is an overview picture how it fits together. I also changed things at the nacell itself, put in vertical stiffeners (1,5 mm stainless steel, bike spokes) otherwise I think the nacelle will be deformed when I put the diacov on.

Made from the same material half loops for apertures for the struts and ruddercables. Made a support for the aerotow hook (was not in the real thing and I will make a catapult hook in the skid)

All the different parts etc, also the lead ballast (550gr, flat lead epoxied together) and battery pack. I also replaced the diagonal wooden struts in the front by tubes. Later it will be covered with 0.6mm ply.

and when put together will create the fuselage

To be continued,

Vincent. |

|

| Revenir en haut de page |

|

|

Frédéric

Psycho Posteur

Inscrit le: 22 Juin 2006

Localisation: Corrèze

Âge: 61

|

Posté le: 13/10/2016 09:07 Sujet du message: Posté le: 13/10/2016 09:07 Sujet du message: |

|

|

|

Salut Vincent !

![[clap]](images/smiles/Clap.gif) ![[clap]](images/smiles/Clap.gif) ![[clap]](images/smiles/Clap.gif) ![[amen]](images/smiles/amen.gif) ![[bave]](images/smiles/bave.gif)

Amicalement

Frédéric

"L'eau plate ne favorise pas le vol de pente." Otto Lilienthal

"In Cyano véritas" Michel Coneuf

"Veni, bibi, vomi" Pasqual VOMITINO

Retroplane fort et vert ! |

|

| Revenir en haut de page |

|

|

bocorvin

Maniaco Posteur

Inscrit le: 17 Aoû 2015

Localisation: Hillegom

Âge: 79

|

Posté le: 13/10/2016 11:42 Sujet du message: Posté le: 13/10/2016 11:42 Sujet du message: |

|

|

|

Salut Frédéric,

Merci pour les compliments!

The construction is a bit unconventional and I am not used to it  ; wood with metal and bolts, it takes a lot of time! ; wood with metal and bolts, it takes a lot of time!

Amicalement,

Vincent |

|

| Revenir en haut de page |

|

|

|